Titan Conveyors

About Titan Conveyors

Company Profile

Titan conveyors are engineered specifically for your needs, without compromise. Titan offers a full range of Rubber, Plastic, Slat, Wire Mesh, Chain Belt and Roller Conveyors for unit handling and bulk handling in both dry and wet environments.

Light Duty

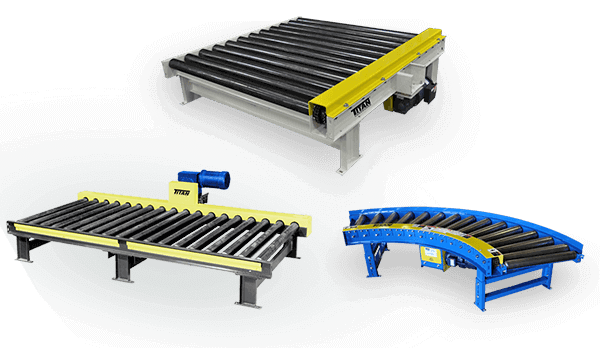

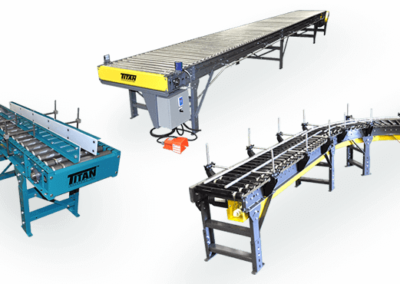

1. Belt Driven Live Roller – When your situation calls for light to medium duty conveying of small packages or close roller centers, the Titan Belt Driven Live Roller Conveyor(s) (BDLR) should be specified.

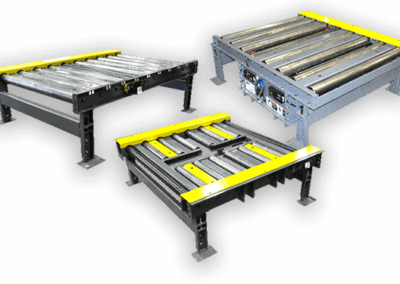

2. Motor Driven Roller Conveyors – Titan ConveyorsTM introduces the Motorized Roller Conveyor, a modular conveyor system utilizing a 24 volt DC drive within a roller. Motorized roller systems are perfect for large zone controlled systems in assembly lines, warehouse situations or unit handling of pallets, totes and cases.

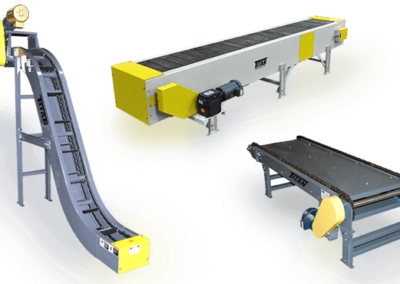

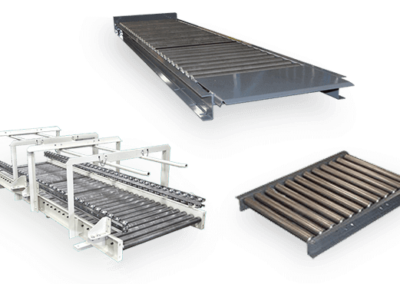

3. Chain Belt Conveyors – Titan custom steel belt conveyors are offered in low and full profiles. They are ideal for a variety of light and heavy duty applications, including machine tool and chip-handling environments, die casting operation, stamping operations, whole plant chip and scrap removal systems, inspection, parts handling and package operation.

4. Incline Conveyor Model 204 – The Model 204 is a light duty floor to floor unit designed for lighter loads and shorter lengths. The 4″ diameter drive pulley will handle numerous products with an end drive or optional center drive and take-up for reversing applications.

5. Gravity Roller Conveyors – There are 5 different models to choose from, ranging in capacities from 95 pounds to 3,000 pounds per roller. Titan offers numerous accessories such as curves, spurs, pop up stops, supports, ceiling hanger brackets, side rails, and optional rollers such as galvanized, stainless steel or plastic coated.

Heavy Duty

1. Chain Driven Live Roller Conveyors – Chain Driven Live Roller Conveyors (CDLRs) are great for handling heavy product with smooth bottom or on pallets.

2. Hinged Steel Belt Conveyor – The steel belt conveyor is the most versatile of conveyors, it can be used to handle nearly every kind of part and all types of scrap. Most applications involve handling metal, with the material often dropping with an impact that other conveyors cannot withstand.

3. Incline Conveyor Model 208 – If a rugged, industrial material handling system is required, consider using the Titan Model 208 Floor to Floor Slider Bed conveyor in your system. The heavy-duty 8″ diameter rubber lagged (vulcanized) drive pulley gives that extra capacity for heavier loads and longer incline sections.

4. Gravity Roller Conveyors – There are 5 different models to choose from, ranging in capacities from 95 pounds to 3,000 pounds per roller. Titan offers numerous accessories such as curves, spurs, pop up stops, supports, ceiling hanger brackets, side rails, and optional rollers such as galvanized, stainless steel or plastic coated.