FLEXCO

Our Brands

FLEXCO

Founded in 1907, Flexco has focused on just one thing; maximizing belt conveyor productivity.

Flexco goes beyond manufacturing belt fasteners, cleaners, and maintenance products to developing real solutions to your belt conveyor challenges.

FLEXCO Light Duty

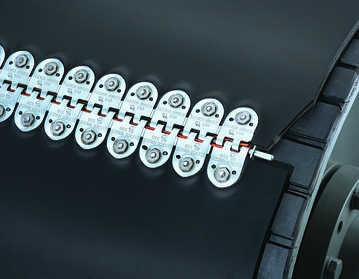

1. Clipper Wire hook

The clipper Wire hook fastening system is designed for belts up to `10mm thick and pulley diameters from 24mm-75mm. Their low-profile design allows for quiet operation with quick installation available in two hook styles: UNIBAR and CARDED fasteners.

2. Clipper G-series fasteners

The Clipper® G Series™ Fastening System provides constant compression, resulting in a flat, uniform splice. Designed for belts 1.5mm-5mm thick with pulley diameters of 40mm-75mm. They are stamped with AISI 316 stainless steel for demanding applications.

3. Alligator Staples

The Alligator® Staple Fastening System is ideal for a wide variety of light- and medium-duty fastener applications. The system features one-piece fastener strips with pre inserted staples for speedy installation keeping downtime to a minimum. Designed for belts 1.5mm-6.4mm thick with pulley diameters of 50mm-102mm. Available in steel, stainless steel, MegAlloy®, and magnetic stainless.

4. Alligator Spiral Lace

The Alligator® Spiral Lace Fastening System is ideal for belt operations with small head pulleys that require both non-metallic and low-profile fasteners. Designed for belts 1.6mm-4.6mm thick with pulley diameters of 10mm-15mm. The removable hinge pin allows for easy cleaning and sanitation of belts.

5. Alligator Plastic Rivet

The Alligator® Plastic Rivet Fastening System produces a non-scratching, non-magnetic and quiet mechanical splice that can be easily dismantled for installation, cleaning, and sanitation. Designed for belts 0.8mm-3.2mm thick with pulley diameters of 38mm-75mm. They are composed of FDA accepted white and blue plastic ideal for the food industry.

6. FGP Food Grade Pre-Cleaner

The FGP Food Grade Precleaner meets the highest standards for food processing. The cleaner is easy to install, easy to maintain and disassembles in a snap for regular cleaning and sanitization. There are several blade options to meet your application-specific needs: white, blue, metal detectable blue, and metal detectable dual durometer blue. Designed for pulley diameters of 50mm-267mm and available in standard blade widths from 12″-60″ (300 mm to 1500 mm).

7. EZP1 Pre-cleaner

The EZP1 Precleaner requires only 4″ (100 mm) of horizontal clearance for correct installation and fits most conveyor structures. Available with blades for standard (purple), high-temp (yellow), ultra high-temp (red), or chemical resistant/food grade (white) applications of widths 12″ to 72″ (300 to 1800 mm). Designed for pulley diameter of 10″-36″ (250 to 900 mm).

8. Tatch-A-Cleat

Designed to improve incline conveying and material containment, our easy-to-install Tatch-A-Cleat® belt cleats, pegs, lugs, and V-guides can restore full carrying capacity to your incline or conveyor belts within minutes – without removing your belt from the conveyor.

9. NOVITOOL AERO Splice Press

The Novitool® Aero® Splice Press offers the latest technology to create a superior endless splice, typically in less than 10 minutes. All necessary components are compactly self-contained, making the press easy to use, store, and transport.

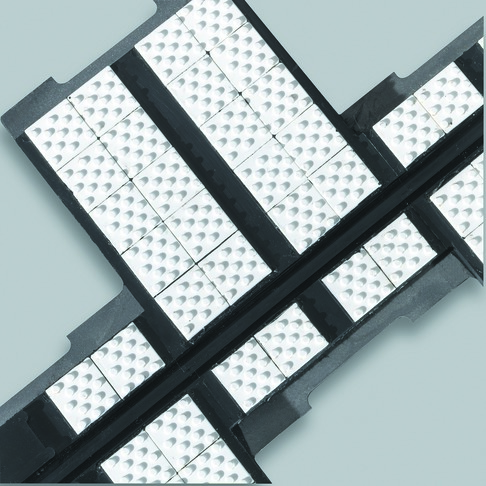

10. Weld-On pulley lagging

Flex-Lag® Weld-On™ Pulley Lagging features a patented gear-tooth design. This eliminates the wide gutters present in conventional weld-on lagging products and minimizes problems associated with vibration, cleaner chatter, and overall belt cleaner compatibility.

FLEXCO Heavy Duty Products

In heavy-duty applications like coal, cement, mining, and aggregate, there are two main belt fastener types: Hinged Plate and Solid Plate. Hinged plate fasteners, often used with small pulleys, are installed into each end of the belt and then joined together and held in place with a pin. Solid plate fasteners consist of one plate that is installed into both ends of the belt and fastened together. Solid plate fasteners are used with larger pulleys and for applications that require a sift-free splice.

1. Bolt Solid Plate

The Flexco® Bolt Solid Plate Fastening System produces a strong, sift-free splice perfect for sand, gravel, crushed stone, and cement. Designed for belts 5mm-50mm thick with pulley diameters of 300mm-1220mm.

2. Bolt Hinged

The Flexco® Bolt Hinged Fastening System is ideal for belt conveyor applications subject to length adjustments and perfect for applications with belts operating over small pulleys. Designed for belts 6mm-16mm thick with pulley diameters of 150mm-225mm.

3. Rivet Hinged

The Flexco® SR™ Rivet Hinged Fastening System is ideal for use on rubber-plied and PVC solid woven belting and for worn belts unfit for vulcanized splices, delivering performance and long life with easy installation. Designed for belts 3mm-25mm thick after skiving with pulley diameters of 125mm-1066mm.

4. MSP Standard Mine-Duty Precleaner

The MSP Standard Mine-Duty Precleaner is a mine-tough design that offers simple installation, quick maintenance, and effective cleaning results with an affordable price tag. Designed for pulley diameters of 16″ to 42″ (400 to 1050 mm) and available in standard blade widths from 24″ to 84″ (600 to 2100 mm).

5. Slider/Impact Beds

Flexco Impact Beds are designed to offer a simple and effective means of protecting the belt in the load zone. Specification and installation of the bed is made easier with adjustable trough angles, while still providing the rugged durability found with all Flexco products. The series features universal components that result in an effective, yet affordable, solution.

6. Weld-On pulley lagging

Flex-Lag® Weld-On™ Pulley Lagging features a patented gear-tooth design. This eliminates the wide gutters present in conventional weld-on lagging products and minimizes problems associated with vibration, cleaner chatter, and overall belt cleaner compatibility.