Martin Sprocket & Gear

About Martin Sprocket & Gear

Company Profile

Martin Sprocket & Gear was founded in 1951. Over the decades Martin has expanded through machining, fabrication, forging, casting, powdered metal technology and machined & injection moulded plastic of power transmission components, material handling products and industrial hand tools.

Martin Light Duty

1. Sprockets – Martin offers a complete line of cast iron, adjustable, engineered class, idler and made to order sprockets.

2. Standard Drum Pulleys – Martin Elite pulleys are manufactured for standard applications such as food, bottling and poultry industries.

Martin Heavy Duty

1. Equal Troughing Idlers – Equal Idlers are designed to support the belt and transport material on the carrying side of the belt. Equal idlers typically consist of 3 rollers with wing rolls at 20, 35 or 45 degree inclinations. Martin Idlers are designed to meet or exceed all Conveyor Equipment Manufacturers Association (CEMA) load standards.

2. Steel Returns – Steel Returns are used to support the belt on the return side when the conveyed material is not sticky, corrosive or excessively abrasive. These rollers are available with a variety of coatings suitable for the specific application.

3. Impact Troughing Idlers – Impact Troughing Idlers are located at loading and transfer points. The rollers are equipped with rubber discs that cushion the impact and reduce costly belt damage. Impact idler frames are reinforced to reduce bending and withstand heavy material loads.

4. Heady Duty Drum Pulleys – Drum pulleys are manufactured from thick wall pipe or tubing, with a crowned face or flat face. Martin has standard duty, quarry duty, mine duty and machined drum pulleys.

5. Heavy Duty Wing Pulleys – Martin Wing Pulleys are constructed from extremely heavy materials and are recognized in the industry as the most aggressive CEMA grade stock pulley on the shelf.

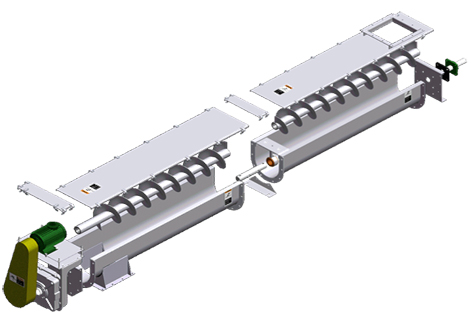

6. Screw Conveyors – The ideal solution for hard-to-transport materials ranging from irregularly shaped dry solids such as scrap wood and metals, to semi-liquid and sticky materials including pulp, compost, food-processing refuse, hospital waste, and wastewater products.

7. Bucket Elevator – Martin manufactures Bucket Elevators in a variety of styles and configurations, including standard duty, mill duty, super capacity, high speed and more. These Bucket Elevators include Centrifugal Discharge and Continuous Discharge with chain or belt mounted Buckets.